W/C 11.02.19

6. The Technology Killing Our Brains |

Weekly Event: |

Concept Feasibility Calculations - a workshop by Ben Craven

This week Ben spoke to us about the power of simple calculations to quickly judge the feasibility of a concept. It’s a great time saving tool which I will definitely use in future projects in an attempt to stop myself perusing unrealistic ideas.

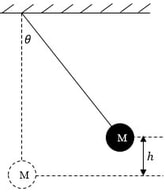

Something that I realised isn’t so great is my mental arithmetic. I was a fourth year engineering student watching in awe as Ben quickly worked through the numbers in his head. They weren’t even particularly difficult. I could have worked them out, but I’m completely calculator dependant – my first thought was to reach for the one in my phone. It’s funny how my brain can grasp complex engineering modules at university, but I don’t consider using it for basic maths. I think we have become so reliant on technology for basic skills. It’s not that we can’t do it, but we delegate, and become unpractised and inefficient. I saw this recently in a 1st year engineering laboratory that I teach. The students are faced with a simple pendulum experiment. It has markers on so that the pendulum can be released from a set angle. Then the students are asked to start the pendulum from 60 degrees – but the scale only goes up to 40 degrees. The solution to which is to use basic trigonometry to work out the equivalent height. This usually results in some head scratching and the waving around of rulers until the height it worked out. But not this time. The students downloaded a spirit level app to let their phone do the maths for them. Intuitive, I thought at first; but then I realised that the more we get technology to think for us, the less able our brains are to solve problems. If we keep getting machines, apps and google to do our thinking for us, what will be left of our brains? |